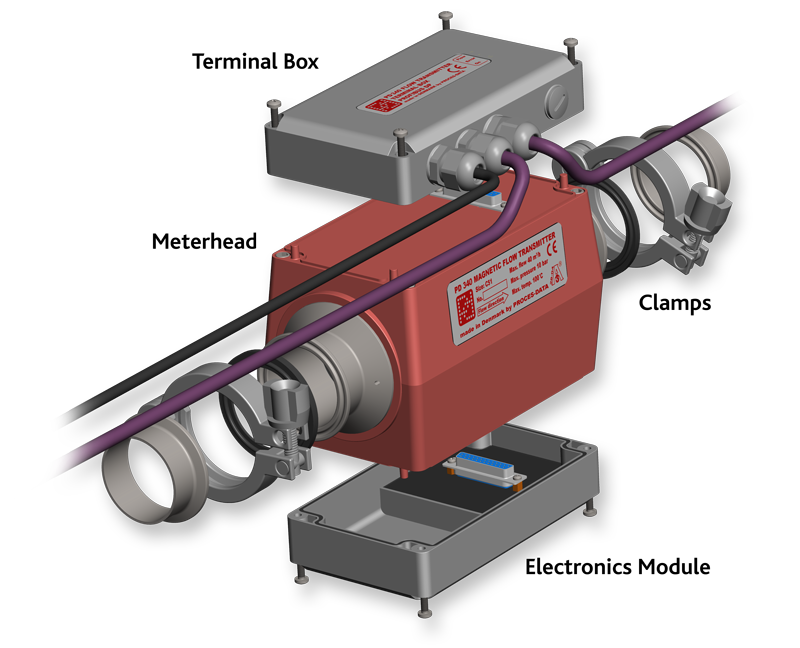

High precision for sanitary applications – PD 340 Series

| Common features for all versions • Suitable for sanitary applications – Designed especially for the food industry. • No moving parts – No maintenance. • Volumetric measurement in m³, litres, U.S. gallons etc. • Robust and compact design – Easy to mount, even in difficult applications. • Factory configured to suit customer requirements. • Constructed to be independent of variations in flow profile. • High accuracy, even if the viscosity or the liquid changes. • Change between different media liquids containing solids without any need for recalibration. • Simple display connection (PD 210). • Two built-in counters for totalising the volume flow. • Optimised for high accuracy and linearity. Using the linearising function, it is possible to measure within a 1:100 turn down range. Therefore the meter can normally be chosen to have the same size as the diameter of the pipe work, and the cost of installation and any pressure drop can be minimised. |

| Specific features for the standard and extended versions • Batch control function. • Two pulse outputs. • Inputs for temperature sensor and digital signal. |

| Additional features for the extended version • 4-20 mA output. • Built-in PI flow controller. • 3-phased output. • P-NET fieldbus communication interface (IEC 61158). |

| Exclusive features for the Profibus version • PROFIBUS DP fieldbus communication interface (IEC 61158). • Input for count stop. • External diodes for power, flow rate and error state. • Physical switches for easy addressing. |